A “Smart Field” concept for optimum development

Options

A “Smart Field” concept for optimum development

Background

Interestingly, there is neither common term to define the abovementioned phenomenon, nor clear understanding of what is it exactly. Different companies develop and adopt similar solutions called “Smart Fields”, “e-Fields”, or “Fields of the future”. Sometimes, plain English terms are used in the Russian language such as Smart Field or iField. And that is not an exhaustive list. Today, it is rather thankless to search for distinguishing features and try to classify those different types because even focused experts fail to come to an agreement for that matter. That is why we will use those terms as synonyms and will focus on the effect that may be achieved upon adoption of intelligent technologies at the producing field.

Sometimes, the “intelligent” concept encompasses state-of-the-art methods of exploration and development, but in-depth analysis of this matter would be a subject of a separate article.

It’s time to become smarter

The only thing that experts have no doubts about is the fact that for fields and deposits, smart technologies is a critical need of today and certainly of tomorrow. Some people even say that adoption of intelligent technologies will soon become an inevitable condition for survival of oil and gas companies worldwide in a competitive environment.

However, not all experts are that peremptory. Thus, Mikhail Cherkasov, Director of Oil and Gas Corporate Service Department at Schneider Electric, thinks that fields with flowing wells may remain profitable without Smart Field components. Unfortunately, such mineral resources are the exception rather than the rule. In Russia, like in most oil producing regions of the world, one cannot go without smart technologies. “Taking into account that production volumes at the existing fields are decreasing, adoption of Smart Field technology and a possibility to manage the oil reservoir may be considered as a strategic factor. Russian companies understand it perfectly well and are ready to invest money and other resources in this concept even today since it eventually will result in cost optimization and increase in profits”, says the expert.

“Russian oil and gas industry stands at a pivotal moment today”, thinks Stanislav Makushkin, Business Development Manager in Oil & Gas segment at Eaton Russia. “The thing is that the fields with unique resources that have been in operation from the 1960s -1970s are now running out of the so called “high-gravity oil”, and on the contrary, the volume of hard-to-recover reserves is growing. As a result, the oil recovery factor decreases.

Given the situation, it is obviously required to change the methods of oil exploration and production that have been developed for over 50 years. Oil production companies are forced to proceed to works at the deposits located at the depth of more than three kilometers. Such types of deposits are characterized by complicated mining and geological conditions, higher temperatures and pressure, different fluid dynamics. Revolutionary theoretical insights and technical solutions are required for development of such oil fields.

According to Artem Vlasov, Academic Secretary and Innovation, Patent and License Team Leader of PermNIPIneft (LUKOIL-Engineering branch), nowadays depletion of reserves of producing fields and remoteness of promising hydrocarbon deposits makes oil companies adopt new technologies in order to reduce the prime cost of oil production and to increase the fields productive capacity at all stages, from exploration activities to soil remediation.

“Under the given conditions, it is possible to find the optimum technically and economically feasible way of development and operation of an oil and gas property only by using an integrated comprehensive approach to achieve the ongoing production objectives”, believes Artem Vlasov. “Such a decision is integrated to the i-Field concept which allows for continuous optimization of the field development resulting in rise in profitability of hydrocarbon reserve development”.

Crouse-Hinds series equipment (photo by Eaton)

Crouse-Hinds series equipment (photo by Eaton)

How intelligence can help

Using intelligent solutions allows reaching the key objectives set before oil and gas companies. According to Stanislav Makushkin, adoption of Smart Field technologies is first of all required to use the growing stock of wells in the most efficient way, to reduce operational expenses, to accelerate production, and to increase the production output.

“A smart field provides a possibility to manage production in order to increase oil or gas output on the one hand, and to optimize costs for consumed energy resources on the other hand”, explains Mikhail Cherkasov. “Besides, thanks to intelligent systems, it is possible to manage the oil reservoir and to control the production process which extends OGF life.

Of course, the practice when absolutely anything is worth doing just to meet the production plan (even if that causes irreparable damage to the field) must become history.

For maximum efficient field management, it is important to ensure business controllability and transparency of all processes. The smart technologies provide an opportunity for solving this task by delivering a vast amount of data from telemetry systems in the real time mode. The data analysis allows making prompt and accurate managerial decisions and ensures effective planning of geological and technical events, equipment maintenance and repair.

Also, it is important to note that management of a large number of wells may be organized centrally as well as remotely.

However, it would not be right to think that a “Smart Field” is just a fashionable term for the production automation system. “It is not enough just to equip the producing well stock with sensors and to improve the automation and dispatching level on site. All of the above certainly helps to increase the cumulative oil output and to efficiently eliminate complications arising in the producing well stock, but it does not give a possibility to evaluate long-term prospects of the oil and gas field development as a whole”, adds Artem Vlasov. And smart technologies do make it possible.

According to Mikhail Cherkasov, among essential advantages of smart fields, there is a possibility to adjust to certain conditions and to ensure feedback-based corrective actions in the real time mode. Besides, thanks to Smart Field, it becomes possible to perform precise simulation modeling of different events and scenarios. Virtual approbation allows avoiding experiments with the real facility by saving money and preventing hypothetical emergency situations. Among other things, an intelligent system provides a short-term outlook of the field condition. “The way we see the “Smart Fields” project lets us assume that all services will receive information for the purpose of constant development optimization in order to obtain production output in the short term and to add value throughout the life cycle in the long term”, explains Andrew Mabian, Deputy Director of Production Operations at Salym Petroleum Development (SPD). “The Smart Field technology makes sure a feedback is received in the real time mode, which information may be used by the company specialists to track performance of each well, to model it by using integrated field management tools, to determine whether any corrective actions are required, and to perform those corrective actions on each and every well by using automated management systems. Such approach ensures the best solution of issues related to constantly growing number of wells that need management subject to maintenance of the operating expenses level”. Stanislav Makushkin also believes that by adhering to the Intelligent Field concept, special attention must be paid to anticipation and prevention of accidents since oil and gas emergencies or machine idle time may often turn into severe financial losses.

Smart Field components

An i-field always starts from building of a geological and technological simulation model. Without knowing the reservoir specifics, without having an idea of how the production process must be organized, it is impossible to create a management system. It is not for nothing that some experts think that “smart technologies” are better fit for fields at the advanced stage of development since the latters are thoroughly explored and analyzed.

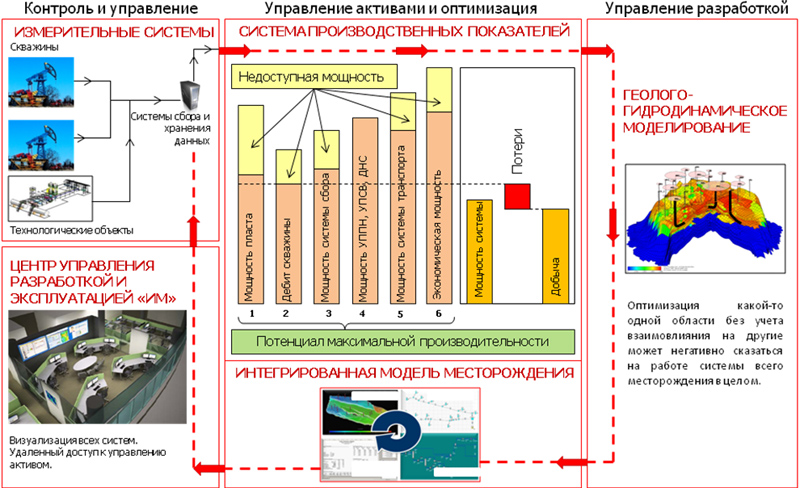

“The production forecast and growth of the oil recovery factor as well as optimization of operational and capital expenses in the Smart Field concept may be evaluated thanks to generation of an integrated model of the field, its adaptation to real conditions and calculation of optimum ways of the OGF development”, says Artem Vlasov. “An integrated model combines models of the reservoir itself and models of the surface facilities. It allows choosing the best option for the field development or production optimization, detecting excessive infrastructure, unnecessary drilling, reasons for equipment failures, hydrocarbon losses due to bottle necks in the gathering system, and increasing economic effectiveness of decisions made as part of OGF management.”

Fig.1. An integrated model receives production facilities parameters in the real time mode, processes them, and issues alternate managerial decisions aimed to reduce the difference between target and actual oil production (diagram by А. Vlasov)

It may be said that one of the key components of a Smart Field is a Smart Well designed to ensure maximum open flow capacity at minimum costs. With the help of telemetry systems, the Smart Well technology provides for optimum modes and reliability of operation of submersible equipment, and is also able to adjust the process mode of the well performance if necessary. “Such adjustments affect the steady mode of the reservoir management”, explains Artem Vlasov. “However, the system of the integrated field model may forecast the OGF development with due account of modified conditions, i.e. adapt all systems to new conditions of OGF exploitation”.

But Smart Field goes beyond this. Generally, the concept includes management systems of a higher level (ERP-systems) that interlink the production itself with other business processes carried out at the facility. Since we are talking about the energy-intensive industry, a critical component of an intelligent field would be “smart” water and power distribution systems.

To transfer telemetry data and control commands, and to share other information, we need reliable and fast communication channels. The system would not be able to operate without the most recent breakthroughs in the field of information technologies such as protocols, communication units, dedicated software.

And in practice…

Basically all major Russian companies have already announced their plans to adopt smart technologies one way or another, and some of them have already been mastering the concept in practice, even though most often we are talking about individual solution components and not the integral system.

For example, Samotlorgazneft JSC (former asset of TNK-BP, and now one of the largest oil production facilities of Rosneft) has been developing the Smart Field program for a few years already.

Another intelligent technologies pioneer is Tatneft JSC that has been actively investing in this concept.

“LUKOIL group also has experience in implementation of individual elements of “smart” systems”, says Artem Vlasov. “Among them, there are geological and hydrodynamic simulation, intelligent well completion, introduction of smart well management stations”.

Coming close to perfection

Salym Petroleum Development (SPD) which is a joint venture of Schell and Gazprom Neft, was the first company in Russia that has equipped the whole well stock with smart fields remote monitoring and management systems. The project started in 2008. As of today, the company installed smart technologies for water intake, injection and treatment at all water injection and supply wells at Salym fields.

Any company employee that has access to the smart fields system domain, whether he or she is on site or in the office, may in real time control and change parameters and levels of water injection and reservoir dewatering as well as delivery parameters of forcing pumps and pressure.

A package of smart technologies allows for remote monitoring and control over the ESP operation and for continuous measurement control. To optimize works related to oil production planning, special software is installed on water intake and injection systems. Also, that system is used for automation of production and waterflood forecasting process.

The information system developed as part of the project helps tracking any and all deviations in well performance in the real time mode by using color indicators. Whenever readings for any well are beyond the preset range, the operator immediately receives an automatically generated e-mail message. Alongside with introduction of the Smart Field technology, a large-scale system training program was provided for production specialists.

“As of today, SPD has already implemented four stages of the project: currently, 100% of the total production and injection volumes of the company are connected to the smart fields system, said Andrew Mabian. “At the present time, works related to installation of automated echo sounders on production wells are about to be completed. Operators will be able to carry out remote monitoring of the liquid level in the well annulus and to adjust the ESP operating conditions if necessary. Besides, SPD is currently equipping the wells with the system of remote monitoring and control of chemicals injection (e.g., scale inhibitors) and is introducing an integrated visual production monitoring system for all wells”.

A visual display system based on the traffic light principle makes sure an operator promptly detects a trouble well (photo by Salym Petroleum Development)

A visual display system based on the traffic light principle makes sure an operator promptly detects a trouble well (photo by Salym Petroleum Development)

Impressive effects

So what do oil and gas companies receive as a result of adoption of smart technologies at their fields? Firstly, they reduce their operating costs which are quite difficult to calculate, and they also reduce their electricity costs by 12-15% (according to different sources). Independent experts believe that with due development of smart technologies, it will be possible to increase the global oil production by 30-50% (if not by 60-70%) thanks to transfer to next-generation technologies.

To avoid telling fortunes, let us turn to some actual results obtained in practice. Thus, according to Andrew Mabian, intelligent optimization of wells operation at Salym fields made it possible to reduce the underperformance level related to unscheduled delays. The response time at the well stabilization stage got reduced. For example, two days used to be required earlier for restart of a well production and for well stabilization, and now, smart fields provide an opportunity to do the same in less than one hour. Along with using other state-of-the-art technologies and approaches, this method allowed increasing the availability factor up to 97%. Also, the mean time between failures (MTBF) of electrical submersible pumps increased significantly: from 500 to 750 days. In general, thanks to implementation of the wells and collectors management project, SPD has increased its production by 2-2.5% per year on the average.

“The second effect has to do with wells and equipment protection”, continues Andrew Mabian. “Now we are able to detect and to prevent abnormalities and deviations from normal operating range at earlier stages in a more effective way. Visual display systems based on the traffic light principle help operators to focus on trouble wells.

Thirdly, smart fields allow us reducing our operating expenses. Thanks to continuous increase of ESP MTBF, we were able to increase the number of well pads manned by the same operator from 1:10 to 1:80. Fourthly, thanks to smart fields, we improved quality of control over wells and fields development at the expense of continuous improvement of the well operating pressure stabilization which resulted in oil recovery growth and improvement of quality of collector integrity control. At the same time, we managed to put hydrocarbon distribution and reporting in order”.

And finally, SPD managed to reduce health and safety risks. The automation phenomenon made it possible to perform operations aimed to optimize oil production in the remote mode. The number of ESP RIH/POOH operations got reduced, and the number of field visits diminished from 40 to 7-8 per month.

Russian difficulties

If smart fields are that good, then why aren’t they operating everywhere? It is clear that the question of new technologies’ economic efficiency is of a high priority in any point of the globe. But maybe there are some specific difficulties in Russia that prevent development of the Smart Field concept?

“Generally speaking, the gap between the Russian market and the global market is not that noticeable”, thinks Mikhail Cherkasov. “However, our oil and gas community is quite conservative, and nobody feels like setting up experiments on their own facilities. Russian companies prefer analyzing international practices first, and only then we come up with a decision whether it is worth to try this new technology.

The apparent distinction of the Russian conditions is that our infrastructure (including communications) is not developed that well. Mainly, Russian oil and gas production facilities are located far from big cities. Besides, wells may be significantly distanced from each other within the same field, and they do need to be combined in the unified integrated system. So it is always a challenge to provide communication at the field, and such challenge may only be met with the help of some serious investment. Besides, many radio frequencies that are normally available abroad are reserved for a number of special uses in Russia. As a result, products designed for the Russian market have to comply with these special conditions”.

“It is worth to mention the three greatest challenges that we faced during implementation of the smart field project”, says Andrew Mabian. “The first one had to do with the geographical features and remoteness of the fields from the infrastructure facilities. The second challenge was related to the fact that such ready-made technical solution was unavailable in Russia. SPD managed to adopt this technology thanks to strong support and assistance provided by one of the company shareholders – Schell who is a worldwide leader in adoption and mastering the Smart Field concept. And finally, like any other innovation, experts met this technology with suspicion and apprehension since people always need time to get used to new tools and to understand their advantages”.

Experts are able to manage a smart field from any point of the globe (photo by Salym Petroleum Development)

Experts are able to manage a smart field from any point of the globe (photo by Salym Petroleum Development)

Looking into the future

Today, the market of intelligent systems for oil and gas companies is still in its infancy. Perhaps, at a later stage there will be more ad hoc companies focused on delivering solutions for smart fields. And perhaps, the integrated approach will be on the trend. Experts tend to share an opinion that the second scenario is much more probable. “It is way more interesting for a customer to obtain a turn-key Smart Field solution since it spares him from many issues related to matching all those small subsystems together”, believes Mikhail Cherkasov. “I think that big projects and integrated solutions will dominate the market. Ad hoc companies existing on the market today that are engaged in providing solutions for BHP and ESP automation might operate in their narrow segment thanks to profound knowledge and skills of their staff. But most likely, they will be absorbed by market giants”.

“The oil and gas market is no different from other markets in this regard”, agrees Stanislav Makushkin. “Normally, a customer is not interested in a technical solution with complicated configurations of many devices, but in development of an integrated management system provided by one vendor, which would be both easy-to-use and cheap in service. That makes it possible for the customer to optimize work and to facilitate his business maintenance”.

Generally, speaking about the market outlook, experts are confident that demand for smart technologies will grow.

“It would be hasteful to expect that all fields will “smarten up” right away”, says Stanislav Makushkin. “Adoption of intelligent technologies requires combined application of innovations for wells and collectors management, development of systematic approach, and establishment of a sound development practice. However, a Smart Field concept guarantees achievement of those tasks that are of the most current concern for oil and gas companies both in Russia and abroad. And that means smart fields will become more and more popular”.

There is no doubt that evolution of smart technologies will continue. Even now, there are references to second- and third-generation smart deposits. They say that a few years from now, plastic bio-nanorobots will totally change all hydrocarbon production concepts. And if the forecasts score, we will soon find out what those wonder mechanisms (and maybe creatures?) can do.

Ekaterina Zubkova

First photo by Salym Petroleum Development

(С) Медиапортал сообщества ТЭК www.EnergyLand.info

Оформить подписку на контент Looking for authoritative content?

Копирование без письменного разрешения редакции запрещено